Summary: In today’s competitive Bitcoin mining landscape, operational efficiency extends beyond hashrate and energy consumption. Rack density and space efficiency (坪效) have emerged as critical factors determining mining profitability. This comprehensive guide explores how strategic facility design, equipment selection, and cooling infrastructure can maximize output per square meter, ultimately reducing operational costs and enhancing ROI for mining operations of all scales.

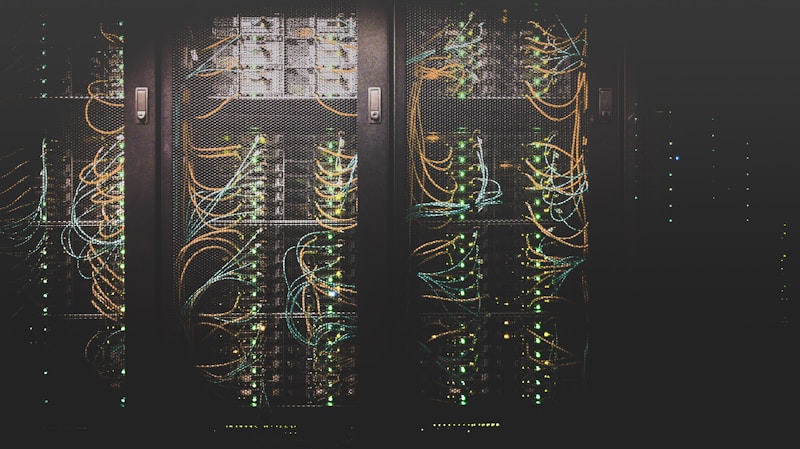

Understanding Rack Density: The Foundation of Modern Mining Facilities

Rack density refers to the amount of computing power concentrated within a given physical space, typically measured in kilowatts per rack or hashrate per square meter. Traditional data centers operate at 5-10 kW per rack, but modern Bitcoin mining facilities can achieve 75-150 kW per rack with proper infrastructure design.

Why Rack Density Matters in 2025

With Bitcoin trading around $102,000 in November 2025, mining profitability depends on maximizing efficiency across all operational dimensions. Space efficiency directly impacts:

- Real Estate Costs: Higher density reduces facility footprint requirements

- Infrastructure Investment: Consolidated operations lower per-unit deployment costs

- Operational Efficiency: Streamlined maintenance and monitoring procedures

- Scalability Potential: Efficient designs accommodate future expansion

Key Metrics for Measuring Space Efficiency

Professional mining operations track several critical metrics:

- Hashrate per Square Meter: Total computational power divided by facility area

- Power Density: Kilowatts consumed per rack or per square meter

- Cooling Efficiency: PUE (Power Usage Effectiveness) ratios

- Equipment Utilization Rate: Percentage of installed capacity actively mining

Selecting High-Efficiency ASICs for Maximum Density

ASIC selection fundamentally determines achievable rack density. Modern mining machines balance three critical parameters: hashrate output, power consumption, and physical footprint.

Top-Tier ASICs for High-Density Deployments

Premium Category: The Bitmain Antminer S21 Pro delivers 234 TH/s at 15 J/TH efficiency, making it ideal for facilities prioritizing maximum density. At 3,510W power consumption, multiple units can be deployed in air-cooled configurations achieving 75-80 kW per rack.

The Bitmain Antminer S21 XP Hydro represents the pinnacle of density optimization, producing 473 TH/s with 12 J/TH efficiency through liquid cooling technology. This allows facilities to achieve 150+ kW per rack while maintaining optimal operating temperatures.

Mid-Range Performers: The MicroBT Whatsminer M60S (170-186 TH/s, 18.5 J/TH) offers excellent density at competitive pricing points. Its 3,441W consumption enables flexible rack configurations balancing density with cooling requirements.

The Canaan Avalon A1566 (185 TH/s, 19.9 J/TH) provides strong performance for operations seeking manufacturer diversity while maintaining high-density deployments.

Cost-Efficient Options for Budget-Conscious Operations

The Bitmain Antminer S19j Pro continues delivering reliable performance at favorable economics. While older generation, its 100 TH/s output at competitive secondary market pricing makes it viable for operations with lower electricity costs seeking to maximize equipment quantity over cutting-edge efficiency.

Comparison Table: Air-Cooled vs. Immersion-Cooled Density Potential

| Cooling Method | Average Rack Density | Facility Space Required (1 EH/s) | Infrastructure Complexity |

|---|---|---|---|

| Air Cooling (Standard) | 20-30 kW/rack | 15,000-20,000 sq ft | Low-Medium |

| Air Cooling (Optimized) | 75-80 kW/rack | 6,000-8,000 sq ft | Medium |

| Liquid Immersion | 150+ kW/rack | 3,000-4,000 sq ft | High |

| Hydro-Cooled ASICs | 100-120 kW/rack | 4,500-6,000 sq ft | Medium-High |

Cooling Infrastructure: The Limiting Factor in Density Achievement

Cooling capabilities ultimately determine maximum achievable rack density. Even the most efficient ASICs generate substantial heat requiring removal to maintain operational stability.

Air Cooling Optimization Strategies

Traditional air cooling remains the most accessible approach for mining operations. Modern facilities optimize airflow through:

Hot Aisle/Cold Aisle Containment: Physical separation prevents mixing of hot exhaust and cold intake air, improving cooling efficiency by 20-30%.

High-Velocity Ventilation Systems: Industrial fans move large air volumes quickly, enabling higher density than passive cooling. Properly designed systems support 40-60 kW per rack.

Direct Outside Air (Free Cooling): Facilities in cooler climates leverage outdoor air directly when ambient temperatures permit, reducing cooling costs by up to 60% during suitable seasons.

Liquid Cooling: Unlocking Maximum Density

Liquid cooling technologies enable substantially higher rack densities by removing heat more efficiently than air:

Immersion Cooling: ASICs operate submerged in dielectric fluid that directly removes heat from components. This supports 150+ kW per rack while reducing cooling costs by 60% compared to air cooling. The MicroBT Whatsminer M66S Immersion (298 TH/s) exemplifies machines designed specifically for immersion deployment.

Hydro-Cooling Systems: Water-cooled ASICs like the Bitmain Antminer S21 XP Hydro integrate liquid cooling directly into miner design, combining density benefits with simpler deployment than full immersion systems.

Direct-to-Chip Cooling: Liquid cooling plates mounted directly on processors provide targeted heat removal. This approach suits hybrid deployments requiring specific high-density zones within air-cooled facilities.

Facility Design Principles for Maximum Space Efficiency

Physical facility design profoundly impacts achievable space efficiency beyond equipment selection alone.

Vertical Space Utilization

Modern mining facilities increasingly adopt vertical rack configurations maximizing cubic volume rather than just floor space. High-ceiling designs (20-30 feet) accommodate multi-level racking systems, effectively doubling or tripling capacity per square foot of land.

Modular Deployment Architecture

Containerized mining solutions offer extreme density advantages. Purpose-built containers house complete mining systems with integrated power distribution and cooling infrastructure. These units achieve:

- Rapid deployment (weeks vs. months for traditional construction)

- Density up to 2.5 MW in a 40-foot container

- Flexibility for expansion or relocation

- Factory-controlled quality assurance

Power Distribution Optimization

Efficient electrical infrastructure reduces space waste from oversized distribution equipment:

High-Voltage Distribution: 480V or higher systems reduce conductor sizes and panel space requirements compared to 208V systems.

PDU Placement Strategy: Rack-mounted or overhead PDUs eliminate floor-standing distribution equipment consuming valuable floor space.

Busbar Systems: Overhead busbar distribution can reduce electrical infrastructure footprint by 40% versus traditional conduit runs.

Economic Analysis: ROI Impact of Density Optimization

Understanding the financial implications of density investments helps operators make informed infrastructure decisions.

Capital Expenditure Considerations

Higher-density designs typically require greater upfront investment in cooling and electrical infrastructure. However, this investment generates returns through reduced per-unit costs:

Real Estate Savings: A facility operating at 100 kW/rack requires only 25% of the building footprint compared to a 25 kW/rack design for equivalent total capacity.

Infrastructure Efficiency: Concentrated operations reduce linear distances for electrical runs, network cabling, and cooling ductwork, lowering material and installation costs.

Operational Cost Analysis

Monthly operational expenses demonstrate density advantages:

Example Calculation (1 MW Installation):

- Low Density (20 kW/rack, air-cooled): 50 racks, 5,000 sq ft, cooling PUE 1.40

- High Density (100 kW/rack, liquid-cooled): 10 racks, 1,000 sq ft, cooling PUE 1.08

Assuming $0.50/sq ft monthly rent and $0.06/kWh electricity:

- Low Density: $2,500/month rent + $50,400/month power = $52,900 total

- High Density: $500/month rent + $38,880/month power = $39,380 total

- Monthly Savings: $13,520 (25.5% reduction)

Profitability Table: Density Impact on Mining Economics (Current Conditions)

| Configuration | Equipment Cost | Monthly OpEx | Daily Profit @ $0.06/kWh | ROI Period |

|---|---|---|---|---|

| S21 Pro Air-Cooled Array (20 units) | $95,200 | $6,300 | $156 | ~22 months |

| S21 XP Hydro Array (10 units) | $180,000 | $5,100 | $177 | ~25 months |

| M60S Mixed Deployment (25 units) | $114,250 | $7,750 | $130.50 | ~27 months |

| S19j Pro Budget Array (40 units) | $43,200 | $7,080 | $48.80 | ~30 months |

Note: Calculations assume current Bitcoin price ~$102,000, network difficulty as of November 2025, and exclude facility infrastructure costs for comparison purposes.

Practical Implementation: From Planning to Deployment

Successful density optimization requires systematic planning and execution.

Assessment Phase

Begin by evaluating your operational context:

- Power Availability: Total capacity, voltage levels, and cost structure

- Climate Conditions: Ambient temperatures, humidity, seasonal variations

- Facility Characteristics: Available space, ceiling height, structural capacity

- Budget Parameters: Capital available, financing options, acceptable ROI timeframes

Design Phase

Develop detailed specifications:

Equipment Selection: Choose ASICs balancing efficiency, density potential, and budget constraints. Miners1688 offers comprehensive selection of manufacturers including Bitmain, MicroBT, and Canaan to support diverse deployment strategies.

Cooling Architecture: Match cooling technology to density targets and budget. Air cooling suits entry-level and mid-scale deployments; liquid cooling justifies investment at enterprise scale or extreme density requirements.

Electrical Infrastructure: Size power distribution, backup systems, and monitoring for maximum density configuration, not just initial deployment phase.

Deployment Phase

Execute construction and installation systematically:

Phased Rollout: Deploy in stages to validate design assumptions before full buildout. Start with a representative section achieving target density before expanding.

Thermal Mapping: Monitor temperature distributions with thermal imaging during initial operation. Identify and address hot spots before they impact equipment lifespan.

Performance Validation: Measure achieved density, PUE, and operational metrics against design targets. Adjust configuration as needed to optimize performance.

Future Trends in Mining Density and Efficiency

The mining industry continues evolving toward higher density and efficiency.

Next-Generation ASIC Technology

Manufacturers are developing machines with improved power efficiency and higher hashrate density. Upcoming models targeting sub-12 J/TH efficiency will enable even higher rack densities within existing electrical constraints.

Advanced Cooling Innovations

Research into phase-change cooling, thermoelectric cooling, and hybrid systems promises to push density boundaries further while reducing operational costs.

AI-Optimized Facility Management

Machine learning systems increasingly monitor and optimize cooling distribution, power allocation, and maintenance scheduling in real-time, maximizing uptime and efficiency across high-density deployments.

Renewable Energy Integration

As mining operations increasingly locate near renewable energy sources, facility designs adapt to accommodate variable power availability, with density adjustments based on real-time energy pricing and availability.

Frequently Asked Questions (FAQ)

Q: What is the optimal rack density for a new Bitcoin mining facility in 2025?

A: Optimal density depends on your specific circumstances. Entry-level operations typically achieve 20-40 kW per rack with air cooling. Professional facilities target 75-100 kW per rack with optimized air cooling or hydro-cooled ASICs. Enterprise operations using immersion cooling can exceed 150 kW per rack. The “optimal” density balances your upfront capital budget, available power capacity, cooling infrastructure, and target ROI period.

Q: How does rack density affect mining profitability?

A: Higher density reduces per-unit costs across multiple dimensions: facility rent, infrastructure deployment, maintenance labor, and cooling overhead. Our analysis shows properly implemented high-density designs reduce total operational costs by 20-35% compared to low-density configurations. However, higher density requires greater upfront investment in cooling and electrical infrastructure, so profitability improvement depends on operation scale and duration.

Q: Can I increase density in an existing air-cooled facility?

A: Yes, but with limitations. You can improve density in existing facilities by upgrading to more efficient ASICs like the Antminer S21 Pro, implementing hot aisle/cold aisle containment, adding supplemental ventilation, and optimizing airflow patterns. However, air cooling fundamentally limits maximum achievable density. Typical improvements reach 40-60 kW per rack maximum. Further density increases require transitioning to liquid or immersion cooling systems.

Q: What are the main challenges of high-density mining operations?

A: High-density deployments face several technical challenges: heat removal complexity requiring sophisticated cooling systems, electrical infrastructure demands with heavy-gauge conductors and distribution equipment, equipment reliability concerns as higher temperatures accelerate component wear, and initial capital requirements for advanced cooling technology. These challenges are manageable with proper planning and quality infrastructure investment.

Q: How do I choose between air cooling and liquid cooling?

A: Consider these factors: Operation Scale – Liquid cooling justifies cost at 5+ MW scale; smaller operations benefit from air cooling simplicity. Available Capital – Liquid cooling requires 30-50% higher upfront investment. Technical Expertise – Air cooling suits operations with general facilities experience; liquid cooling needs specialized technical knowledge. Density Requirements – If achieving >80 kW per rack is critical for facility economics, liquid cooling becomes necessary. Long-term Strategy – Plan for your 3-5 year capacity, not just immediate deployment.

Q: What is a realistic timeline for building a high-density mining facility?

A: Traditional construction takes 6-12 months for facility buildout plus 2-3 months for equipment procurement and installation. Modular containerized solutions reduce this to 8-16 weeks total from order to operation. Timeline variables include equipment availability (particularly for newest-generation ASICs), local permitting processes, electrical utility connection requirements, and cooling system complexity.

Q: Where can I source equipment for high-density mining deployments?

A: Miners1688 specializes in supplying equipment for density-optimized mining operations, offering direct manufacturer relationships with Bitmain, MicroBT, Canaan, and other leading ASIC manufacturers. Our technical team assists with equipment selection matching your density targets, cooling infrastructure, and budget parameters. We provide comprehensive support from initial planning through deployment and ongoing operation.

Ready to optimize your mining facility for maximum profitability? Visit Miners1688 to explore our complete range of high-efficiency mining equipment and connect with our technical team for personalized facility design consultation.